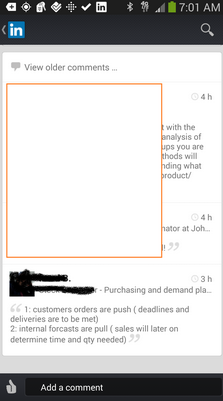

Yes, I know I know, Somebody’s Wrong on the Internet!  I am somewhat ranting this morning, because the screenshot to the right is so disappointing. The redacted person is responsible for implementing Lean in his organization, but I see this with all types of systems.

I am somewhat ranting this morning, because the screenshot to the right is so disappointing. The redacted person is responsible for implementing Lean in his organization, but I see this with all types of systems.

The redacted person, let’s call him Micro, has a fundamental misunderstanding of the guiding principles of how he works. In this case, he believes that customer orders are a push system. Meaning he believes customer orders force work on his production system, rather than events to engage his production system.

For the general public, this is a fairly esoteric concept. But for Lean it’s about as important as an electrician claiming that live wires were okay to grab with your bare hands.

(Trust me, it’s so tempting to go into a lecture on pull systems right now…)

But I’m running into this more and more lately, people who are active in their communities misunderstanding fundamentals of their espoused beliefs. This guy is active enough to participate in open forums, speaking knowledgeably about Lean and answering questions for people just starting out.

Whether you are employing elements of Lean, “Agile”, Six Sigma or any other flavor of standardized process control - you need to grasp the basics first.

In December, I wrote this blog post on making sorbet. In this post, I show that there are fundamental things (a core) to making sorbet. On top of that core you have a lot of leeway to innovate. There is a platform for sorbet that provides it with the minimal structure to be sorbet.

You cannot make sorbet without water. You cannot make sorbet without some sort of sugar. You cannot make sorbet without it becoming cold.

You can make sorbet with just about anything else on earth.

We need to understand the core of our work. We need minimal structure to build upon. Without that structure, we cannot communicate, we cannot plan, we cannot have coherent systems.

In this case, this guy is going to build systems claiming to be Lean that are completely contrary to everything Lean is trying to do.

Please, people who consider themselves coaches, senseis, leaders, managers … learn the systems you are employing and then innovate.